Wareegga jaantuska

Wareegga jaantuska

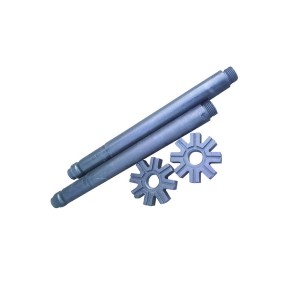

Rotor graphite iyo graphite impeller waxay ka samaysan yihiin garaaf nadiif ah. Dusha sare waxaa lagu daaweeyaa oksaydh khaas ah, nolosha adeeguna waxay ku dhowdahay 3 jeer alaabta caadiga ah. Waxaa si ballaaran loogu adeegsadaa warshadaha aluminium tuurista daawaha.

Nidaamka isdaahirinta ee daawaha aluminium ee dareeraha ahi waa habka ugu muhiimsan ee lagu hagaajiyo waxqabadka dhammaystiran ee aluminium. Nidaamka isdaahirinta, habka isku qasida gaaska isdaahirinta iyo dareeraha iyo ku buufinta rotor-ka garaafka rullaluistemka dhalaalka aluminium ee nadiifinta ayaa ah habka daaweynta ugu horumarsan adduunka. Mabda'a shaqada ee rotor-ka garaafku waa: rotor-ka wareegaya wuxuu jebiyaa nitrogen-ka (ama argon) lagu afuufa aluminiumka dhalaalaya tiro badan oo goobooyin kala firdhisan ah kuna kala firdhiya birta la shubay. Xumbooyinka ku jira dhalaalka waxay ku tiirsan yihiin gaaska farqiga cadaadiska qayb ahaan iyo mabda'a xayeysiinta dusha sare si ay uga soo nuugto hydrogen dhalaalka, xayeysiiska xayeysiiska ah ee adsorb, iyo in laga saaro dusha dhalaalaya sida goobooyinku u soo baxayaan, si dhalaalka loo nadiifiyo. Sababtoo ah goobooyinku way yar yihiin oo way kala firidhsan yihiin, si siman ayaa loogu qasan yahay dhalaalka wareegaya, ka dibna waxay ku wareegaan qaab wareeg ah oo ay si tartiib ah u sabbeeyaan. Waqtiga xiriirka lala leeyahay dhalaalku waa dheer yahay, socodka hawada ee ka dhasha toosan toosan oo toosan la soo dhisi maayo, taasoo markaa ka saareysa haydrogen-ka waxyeellada leh ee ku jira dhalaalka aluminium. Saamaynta daahirinta.

Qalabka aluminium ee aluminium iyo warshadaha wax soo saarka aluminium, waa mid aad u muhiim ah in la yareeyo kharashyada waxqabadka. Marka la eego, rotors-yada garaafka ee ay soo saartay shirkadeenu waxay keeni karaan faa'iidooyinka soo socda. 1. Hoos u dhig kharashka ku baxa howsha 2. Iska yaree isticmaalka gaaska aan caadiga ahayn 3. Yaree waxyaabaha aluminium ee ku jira qoryaha 4. Yaree qarashyada shaqaalaha 5. Hagaajinta waxqabadka, wareegga beddelka dheer 6. Hagaajinta kalsoonida oo yaree kharashyada dayactirka.

Sababtoo ah qeexitaannada router-yada loo yaqaan 'graphite rotors' ee loo adeegsaday khad kasta ama khadadka wax soo saar ee wax lagu ridayo isku mid ma aha. Marka hore, macaamilku wuxuu siiyaa sawirada naqshadeynta asalka ah wuxuuna ku buuxiyaa foomka garaafka rotor-ka buuxa foomka sahanka deegaanka. Kadib, sida ku cad sawirada, oo lagu daro xawaaraha garaafka garaafka, jihada wareegga iyo booska ay ku xiran tahay heerka dareeraha aluminium, falanqaynta farsamada ayaa la sameeyaa, waxaana la soo jeedinayaa iska caabin ka hortagga nabaad guurka ah. Barnaamijka daaweynta Oxidation.

Mashiinka wareega ee garaafka garaafku wuxuu ka samaysan yahay garaaf nadiif ah. Marka lagu daro tixgelinta baahida loo qabo in la jajabiyo goobooyinka, qaabdhismeedka mashiinka ayaa sidoo kale adeegsada xoogga centrifugal ee ka dhashay walaaqidda aluminiumka dhalaalaya si dhalaalku u galo sanka oo uu si siman ugu dhex daro gaaska si tartiib tartiib ah looga saaray si uu u sameeyo gaas / Diyaaradda dareeraha lagu buufiyaa si loo kordhiyo aagga xiriirka iyo waqtiga xiriirka ee xumbada iyo dareeraha aluminium ee aluminiumka ah, iyo hagaajinta saameynta isdaahirinta degassing.

Xawaaraha rotor-ka garaafka waxaa si isdaba-joog ah loogu hagaajin karaa xakamaynta xawaaraha is-beddelka soo noqnoqda, illaa 700r / min. Qeexitaanka rotor-ka garaafku waa Φ70mm ~ 250mm, iyo qeexitaanka qalabka wax lagu duubo waa Φ85mm ~ 350mm. Nadiifinta sare ee anti-oxidation graphite rotor wuxuu leeyahay astaamaha xoogga sare, iska caabinta heerkulka sare, iyo aluminiumka u adkeysiga qulqulka. Nidaamka nadiifinta iyo kala-baxa, dusha sare ee dareeraha aluminium ee ku jira sanduuqa ayaa lagu daboolay nitrogen si loo ilaaliyo, sidaas darteed qaybta rotor-ka garaafka ee ka soo baxa dareeraha aluminiumku wuxuu ku jiraa gaas aan firfircooneyn si looga hortago qiiqa heerkulka sare ee rotor oo sii dheereeya nolosha adeegga rotor.

Qaabka qalabka wax lagu duubo ayaa la hagaajiyay, kaas oo yareyn kara iska caabinta inta lagu jiro wareegga, iyo isqabqabsiga iyo kala soocida xoogga u dhexeeya qalabka wax lagu buufiyo iyo dareeraha aluminium ee aluminiumku aad ayuu u yar yahay. Markaa in heerka kala-baxa uu ka sarreeyo 50%, isagoo gaabinaaya waqtiga dhalaalka iyo yaraynta qiimaha wax soo saarka.